Did you know that D.T.E. can perform mechanical machining more efficiently, using CO2 laser cutting technology? We have implemented it because it is a machine that allows us to be even more competitive and offer a more complete service to our customers.

CO2 laser cutting with CNC technology is based on a system of transmitting the laser beam from a tube to the material through mirrors. The laser produces a beam of infrared lights, which is powered by gas components present in the tube (carbon dioxide, nitrogen, hydrogen, xenon and helium), the percentages of which vary depending on the type of cut, material and thickness to be cut or engraved. This makes laser cutting an extremely precise and versatile process.

CO2 laser technology has many advantages, it is easy, precise, saves material due to its precision and can cut a wide range of different parts, thicknesses and materials, and many times does not require further processing, ensuring high productivity .

The laser cut used in our company develops an installed power of 4000 W in the head, and allows a cutting area that can reach up to 3000×1500 mm.

As for the workable materials and thicknesses, they vary as follows:

| Materiale | Codice materiale | Spessore |

| Iron | S235JR | from 1 mm to 20 mm |

| S355J2 | from 1 mm to 20 mm | |

| Aluminium | Al-5754 | from 1 mm to 8 mm |

| Al-5053 | from 1 mm to 8 mm | |

| Steel | Stainless | from 1 mm to 12 mm |

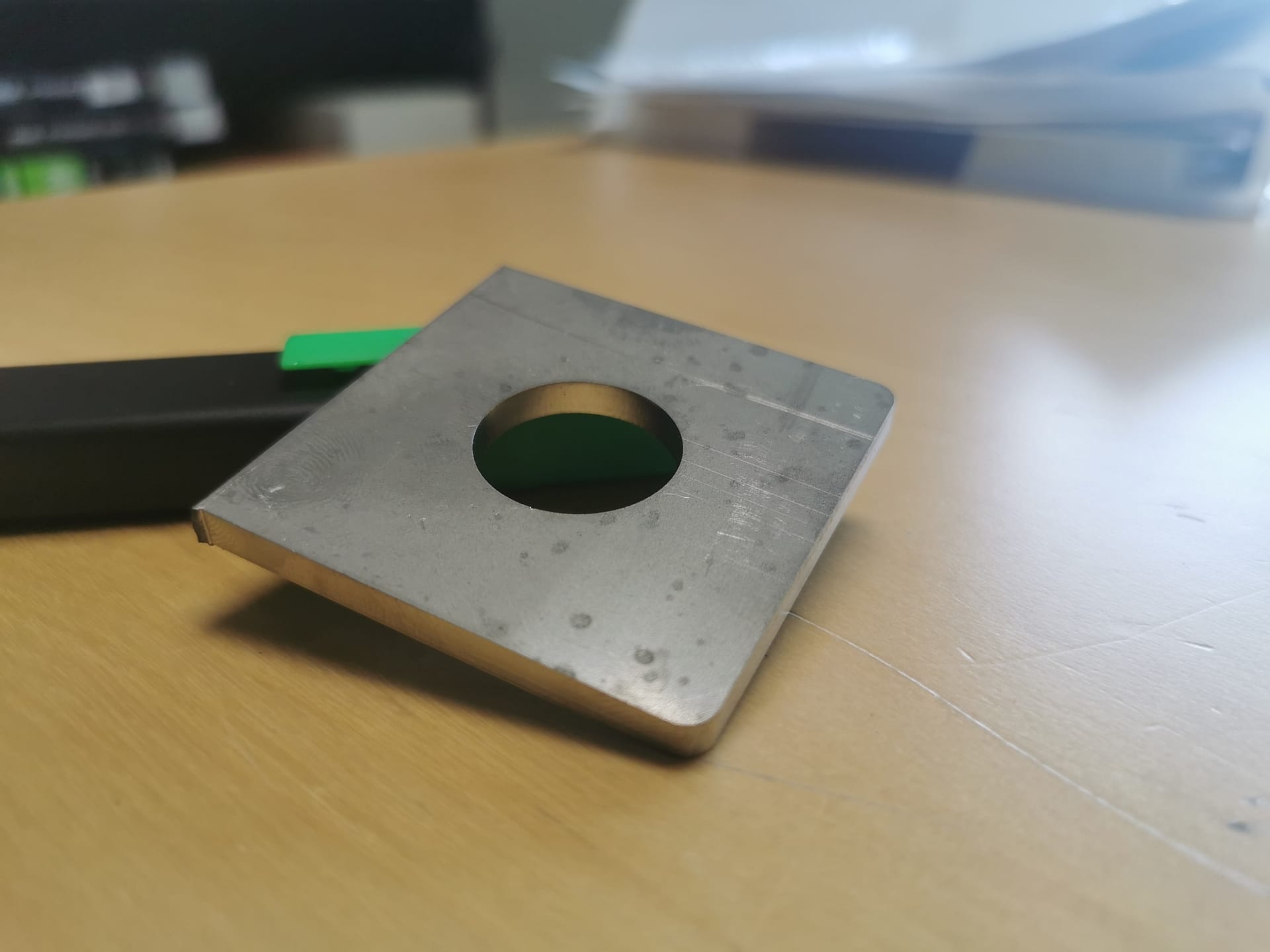

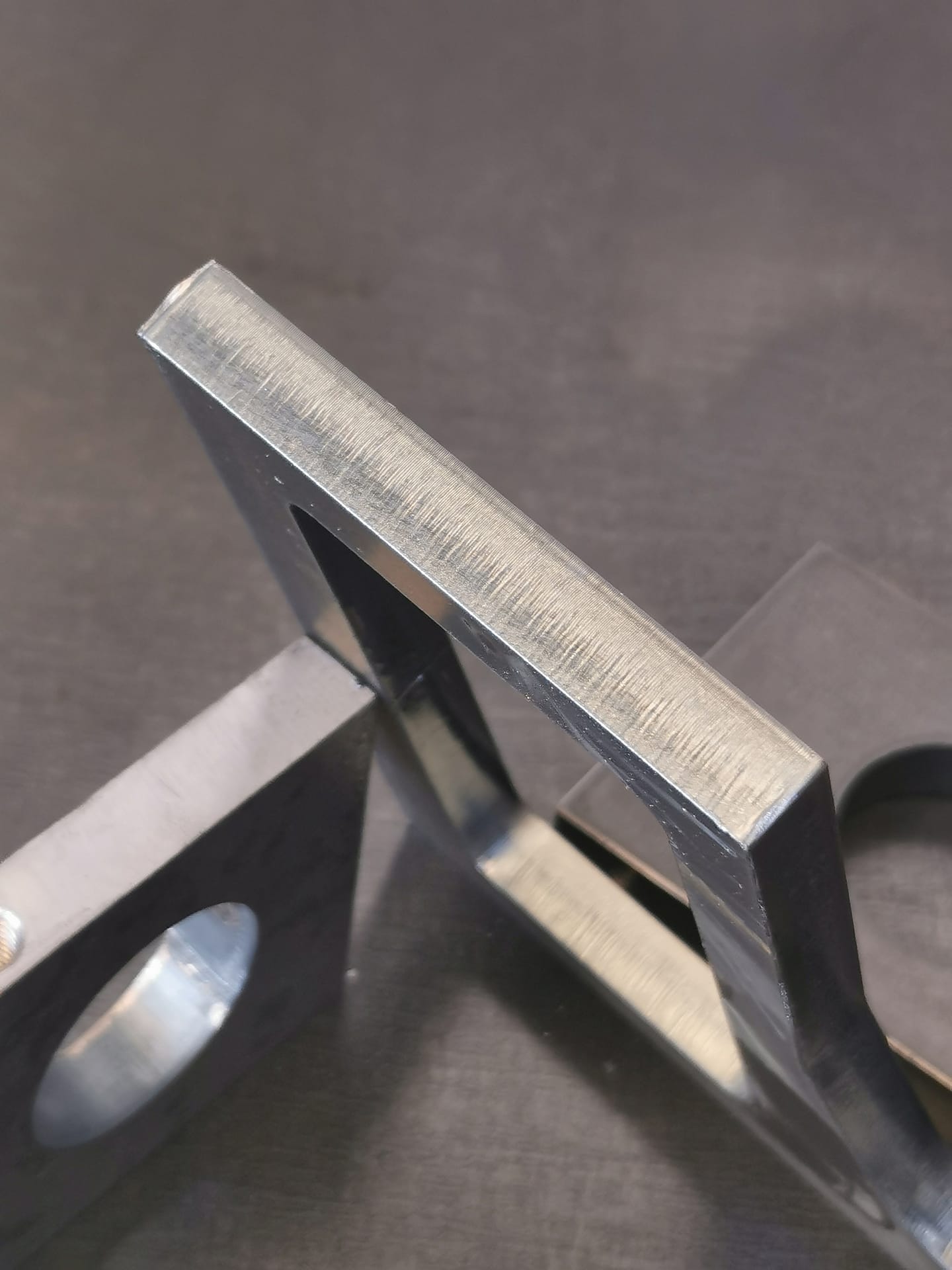

3mm thickness

4mm thickness

10mm thickness

15mm thickness

20mm thickness

Do you know how laser cutting works?

Laser cutting is a thermal separation process: the laser beam strikes the surface of the material and heats it to the point of melting or completely vaporising it. Once the laser beam has penetrated completely into the material at a certain point, the actual cutting process begins. The laser system follows the selected geometry and in this process the material is separated. For a good cut, the adjustment of the distance between the lens and the material to be cut is very important, as well as a jet of compressed area at the cutting point. The higher the laser power, the greater the maximum thickness and type of material that can be cut.

![]()